Le Groupe WeylChem est engagé depuis de nombreuses années pour agir en acteur responsable et durable de l’industrie chimique1. Conscient de l’accélération et de l’amplification des impacts environnementaux – notamment climatiques – et de l’importance de contribuer à leur atténuation, le groupe a souhaité renforcer cet engagement à travers la refonte de sa stratégie RSE « From Good to Great ». L’action climatique est un pilier majeur de cette stratégie, et s’appuie sur la mesure des émissions de gaz à effet de serre (scope 1+2+3), le développement d’objectifs de réduction et d’une trajectoire bas carbone.

Le site de WeylChem Lamotte s’appuie sur une longue démarche d’excellence environnementale et d’amélioration continue :

- Le site est signataire de la charte mondiale du « Responsible Care », démarche d’engagement volontaire de progrès des Entreprises de la Chimie. Il est aussi certifié ISO 9001 (management qualité), ISO 14001 (performance environnementale), ISO 50001 (management de l’énergie), et labellisé Ecovadis Gold 2.

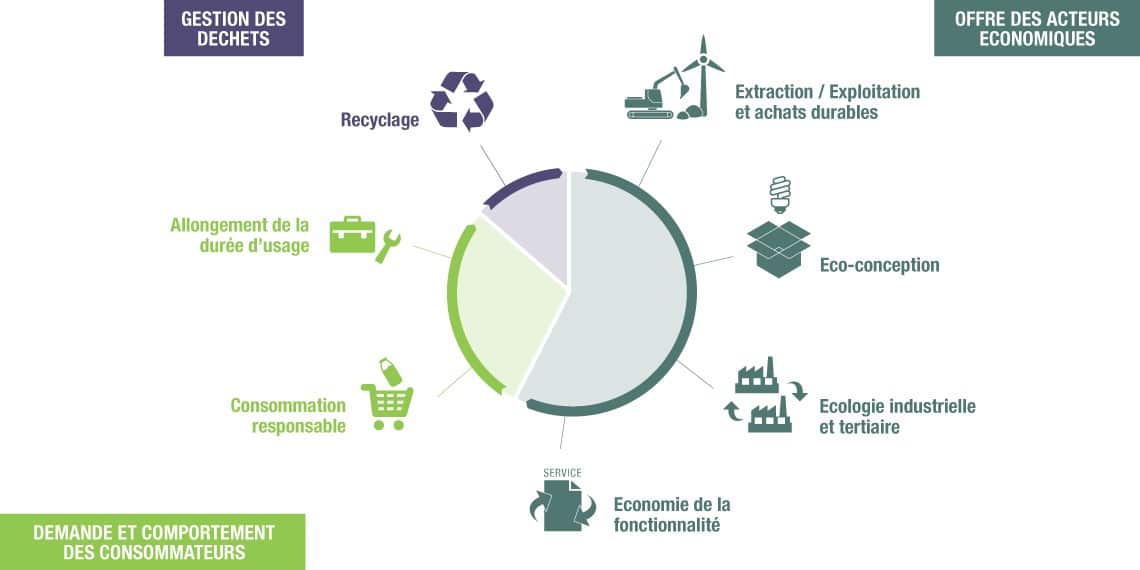

- La circularité est au cœur du fonctionnement de la zone industrielle : l’intégration thermique de la chaleur générée par WeylChem Lamotte permet à tous les acteurs de la plateforme de bénéficier de vapeur décarbonée, ce qui réduit l’utilisation de combustibles fossiles. L’intégration matière et les synergies entre les acteurs évite du transport et donc des émissions. Les déchets sont valorisés, et produisent de la valeur dans une démarche d’économie circulaire, notamment en retournant du carbone au sol.

- Les choix d’approvisionnement sont réfléchis pour équilibrer aspects économiques et impacts. Les fournisseurs sont essentiellement européens pour limiter les distances parcourues et s’appuyer sur des acteurs répondant à des cadres règlementaires exigeants. Le fret ferroviaire, dont l’impact est significativement plus bas que celui du transport routier, couvre 50% des approvisionnements et 25% de ventes. L’optimisation du chargement des camions est aussi un point d’attention.

WeylChem Lamotte est signataire du Responsible Care qui assure l’engagement commun au niveau mondial de l’industrie de la Chimie pour la gestion sûre des produits chimiques tout au long de leur cycle de vie et la promotion de leur rôle dans l’amélioration de la qualité de vie et leur contribution au développement durable.

WeylChem Lamotte est un établissement soumis à la législation des Installations Classées pour la Protection de l’Environnement (ICPE) et est classé SEVESO Seuil haut ce qui implique une surveillance renforcée et l’impact de l’activité de la plateforme est contrôlé par des laboratoires internes et externes à la demande de l’administration qui vérifie les résultats et procède à des contrôles inopinés.

Ces systèmes de management sont certifiés : ISO 14001 Environnement ISO 50001 Energie

Suivi Environnemental

L’eau

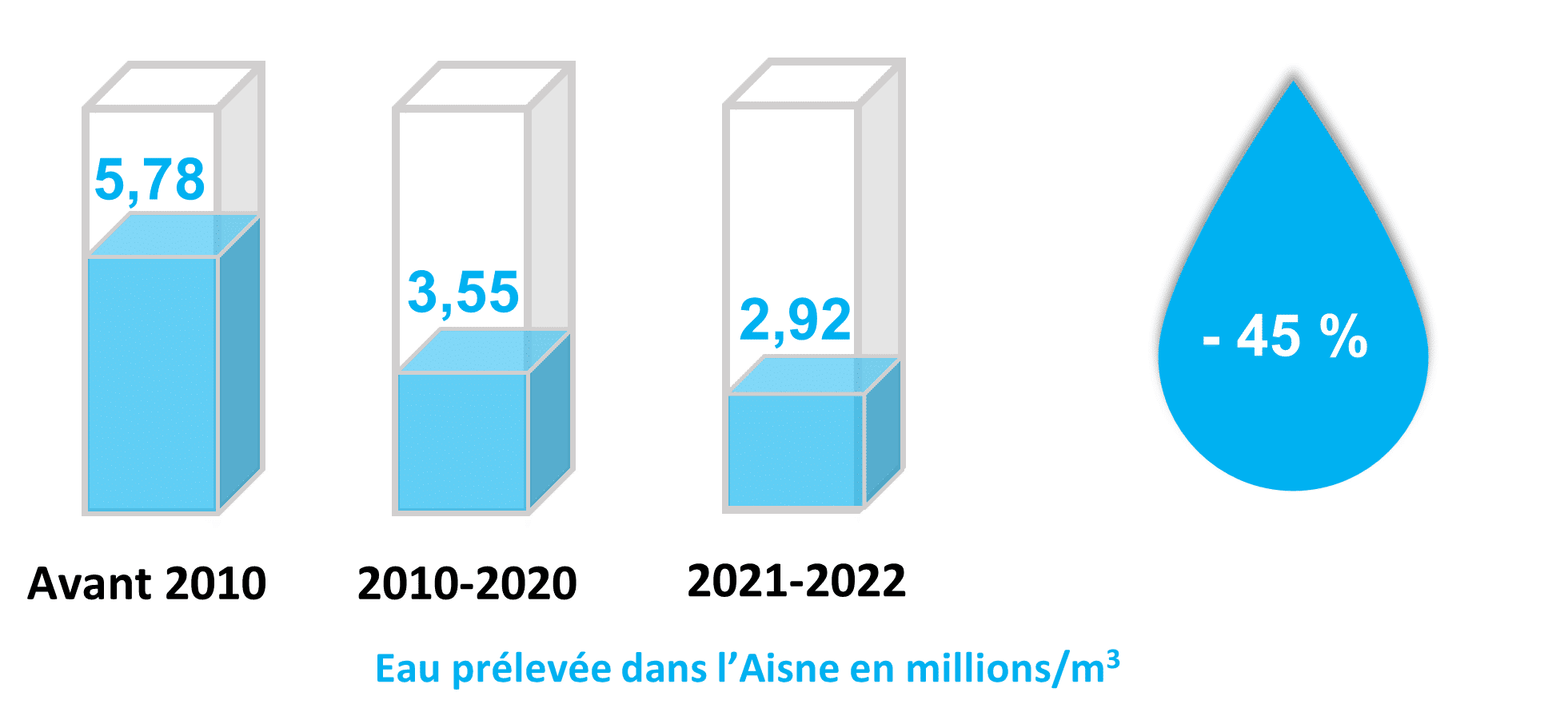

Depuis de nombreuses années, la plateforme s’est engagée dans une politique de réduction de sa consommation d’eau et de préservation de la qualité de l’eau de l’Aisne.

Sur les 20 dernières années, le prélèvement a été réduit de 45 % :

Station d’épuration

Une station d’épuration biologique traite les eaux usées et les eaux résiduaires de la plateforme, soit 5 à 7000 m3 par jour. Sa capacité de traitement est équivalente à une ville de 300 000 habitants. Le rendement d’épuration atteint aujourd’hui des valeurs supérieures à 95 %.

L’amélioration continue des performances de la station de traitement des eaux est un objectif permanent qui permet de réduire l’impact sur la qualité du milieu naturel. Depuis 3 ans, 1 M€ ont été investis dans l’automatisation et le suivi de la station ainsi que dans la séparation des flux entrants.

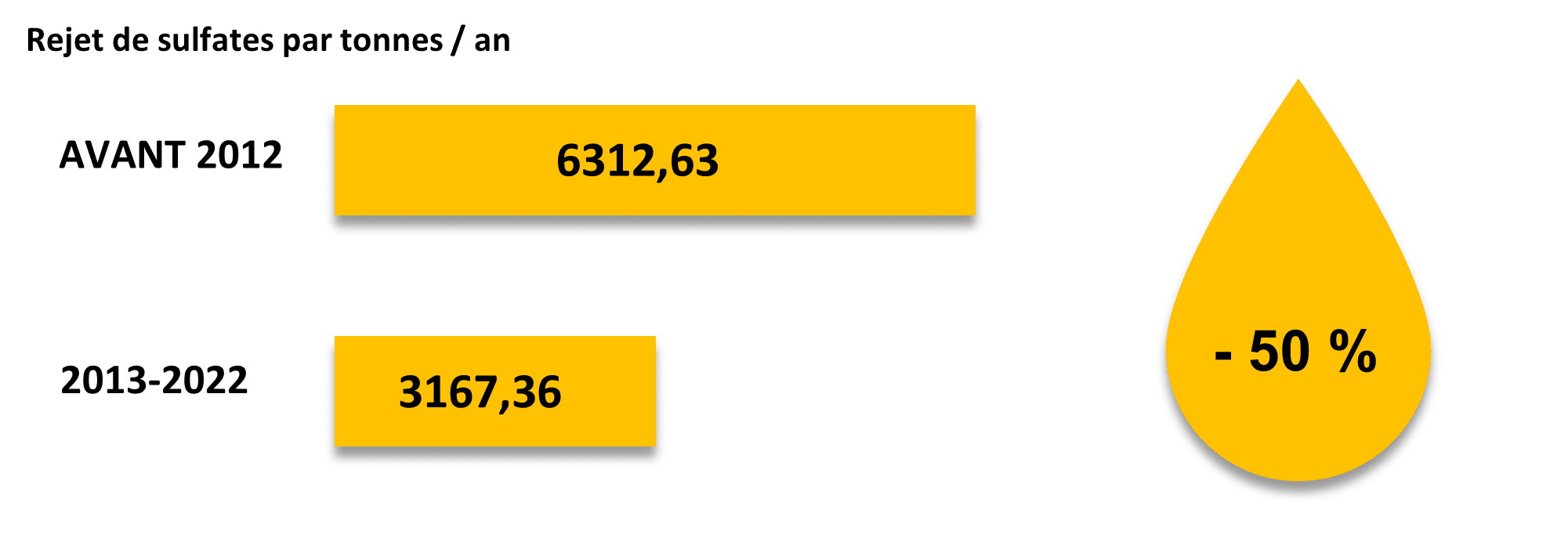

Les sulfates

Une unité de prétraitement récupère et valorise sur le marché de la détergence les sulfates contenus dans les effluents d’un atelier de production ce qui a permis une réduction de 50 % de nos rejets.

Le nickel

Dans le cadre du programme national de recherche de substances dangereuses dans l’eau, un prétraitement d’un effluent de production a permis de réduire de 70 % le rejet de nickel dans l’Aisne.

Une autosurveillance journalière permet de vérifier la qualité des eaux rejetées après traitement, dans le milieu naturel.

Une expertise hydrobiologique annuelle réalisée en période d’étiage confirme depuis plus de dix ans le faible impact de l’activité de la plateforme sur la qualité de l’Aisne.

Air

Gaz à effet de serre

Les productions des unités Glyoxal et Acide Glyoxylique conduisent à une émission importante d’un gaz à effet de serre ; le protoxyde d’azote (N2O) dont le pouvoir de réchauffement est 298 fois supérieur au dioxyde de carbone.

Dès 1993, des essais ont été lancés pour tester différents procédés de destruction de N2O. Ces essais ont abouti en 1997 à la mise au point d’un procédé de destruction catalytique qui a été breveté et à la construction d’une unité industrielle de traitement des émissions de N2O.

La performance et la capacité de cette unité ont été améliorées pour atteindre un rendement supérieur à 95 %.

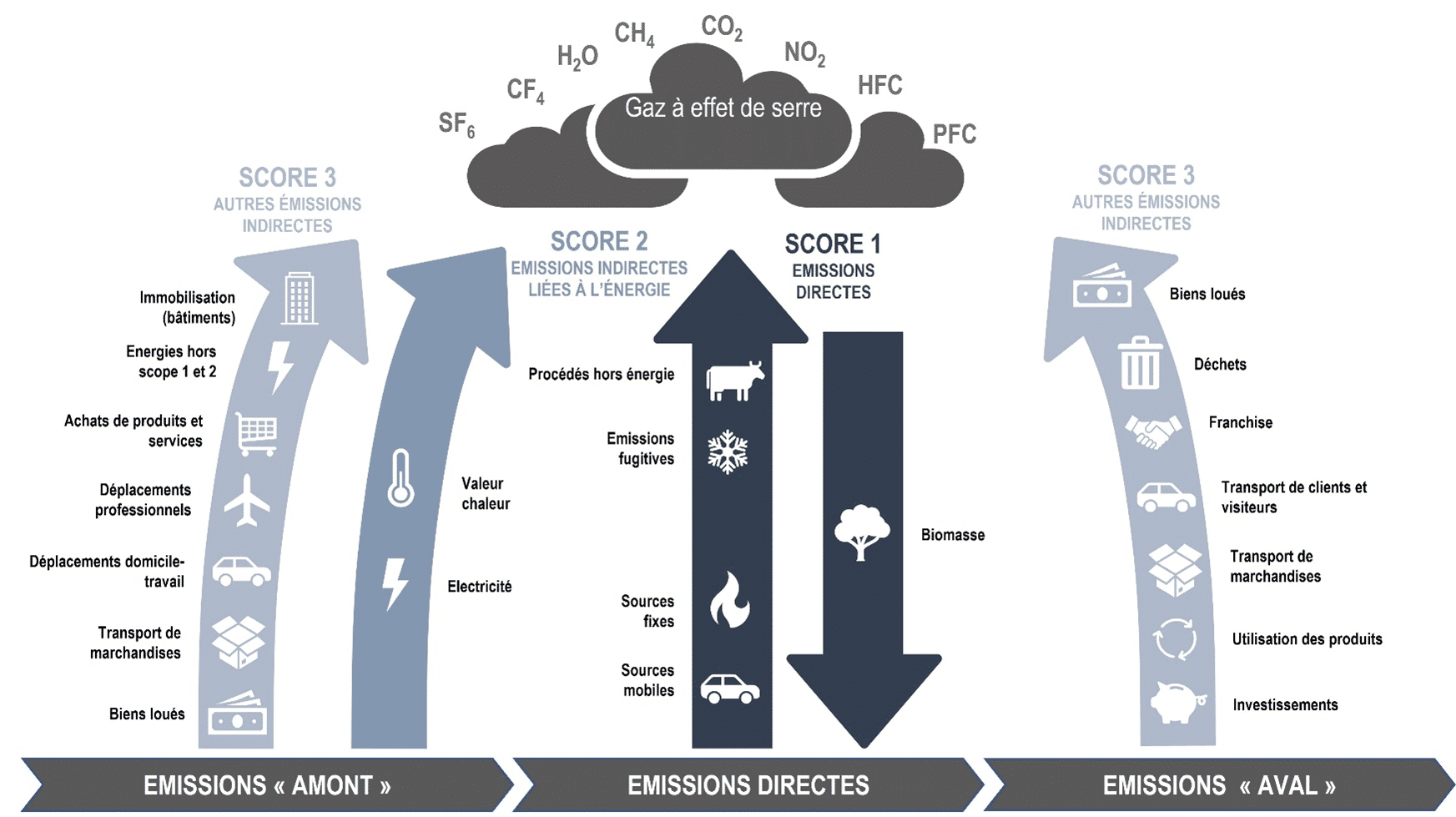

Bilan carbone

Pour compléter ces actions et contribuer à la lutte contre le changement climatique, le site a décidé d’approfondir sa démarche de réduction des émissions de gaz à effet de serre. Un Bilan Carbone® 3 a été réalisé en 2022 sur l’ensemble des scopes 1, 2 et 3 (amont + fret aval/déchets) pour l’année 2021 (327 kt CO2e, dont 103 kt d’émissions directes), et a permis d’identifier des leviers d’action importants.

Le site travaille maintenant à la définition de ses objectifs de réduction et de sa trajectoire bas carbone, ainsi que le développement d’une culture « climat/carbone » au travers de sa stratégie RSE, d’outils de pilotage, et la formation de l’ensemble des collaborateurs aux enjeux climat, carbone, énergie.

Certains des leviers de réduction sont d’ores et déjà en cours de réalisation. Ainsi, un investissement de plus de 15M€ a été approuvé mi 2022 pour moderniser la production de glyoxal 4. Ce projet réduira l’empreinte carbone du site d’environ 20 % et les émissions directes de 30 %, ce qui est l’objectif de la Stratégie Bas Carbone à l’horizon 2030 pour l’industrie. Le démarrage du projet est prévu en 2024.

De nombreuses autres actions sont également en cours d’étude, par exemple :

- La poursuite des efforts d’efficacité énergétique et d’intégration

- La décarbonation de l’énergie : installation de panneaux photovoltaïques sur une zone en friche de la plateforme, remplacement de l’approvisionnement en gaz par des combustibles alternatifs

- Un travail avec les fournisseurs pour mieux comprendre les spécificités de production pour une même matière première et identifier le cas échéant des mieux-disants environnementaux.

- Renforcement du report modal, avec un investissement en cours pour pérenniser l’infrastructure

Weylchem Lamotte s’appuie sur les compétences et la motivation de ses équipes et de ses partenaires à l’innovation, pour fournir des produits s’inscrivant dans une démarche de développement durable et de baisse des émissions de gaz à effet de serre.

Pour info :

Le Bilan Carbone® est une évaluation de la quantité de gaz à effet de serre (CO2, CH4, N2O, HFC…) émise (ou captée) dans l’atmosphère sur une année du fait des activités d’une organisation. Cela inclut les émissions directes – eg combustion d’énergies fossiles sur site – mais aussi les émissions indirectes telles que celles liées aux approvisionnements, transport, achats d’énergies, déchets. WeylChem Lamotte a souhaité réaliser ce bilan, allant au-delà des exigences règlementaires (bilan obligatoire pour les entreprises > 500 personnes).

Pour info :

Le Bilan Carbone® est une évaluation de la quantité de gaz à effet de serre (CO2, CH4, N2O, HFC…) émise (ou captée) dans l’atmosphère sur une année du fait des activités d’une organisation. Cela inclut les émissions directes – eg combustion d’énergies fossiles sur site – mais aussi les émissions indirectes telles que celles liées aux approvisionnements, transport, achats d’énergies, déchets. WeylChem Lamotte a souhaité réaliser ce bilan, allant au-delà des exigences règlementaires (bilan obligatoire pour les entreprises > 500 personnes).

Bilan carbone

Forte de l’expérience acquise sur le traitement catalytique du protoxyde d’azote, la plateforme a investi dans un traitement catalytique des oxydes d’azote qui permet une réduction de 85 % sur les 20 dernières années.

Réduction des gaz à effet de serre

Les productions des unités Glyoxal et Acide Glyoxylique conduisent à une émission importante d’un gaz à effet de serre ; le protoxyde d’azote (N2O) dont le pouvoir de réchauffement est 298 fois supérieur au dioxyde de carbone.

Dès 1993, des essais ont été lancés pour tester différents procédés de destruction de N2O. Ces essais ont abouti en 1997 à la mise au point d’un procédé de destruction catalytique qui a été breveté et à la construction d’une unité industrielle de traitement des émissions de N2O.

La performance et la capacité de cette unité ont été améliorées pour atteindre un rendement supérieur à 90 %.

De réduction des émissions de Nox

Depuis 2005

Réduction des gaz acidifiants

Forte de l’expérience acquise sur le traitement catalytique du protoxyde d’azote, la plateforme a investi dans un traitement catalytique des oxydes d’azote.

D’émission de NOx

Depuis 2005

Energie et Transport

Production et consommation d’énergie

WeylChem Lamotte est certifié ISO 50001. Cette norme internationale vise l’amélioration de la performance énergétique. Elle a pour objectif de faire face à la rareté de l’énergie et à son augmentation durable de prix, tout en contribuant à la réduction des émissions de gaz à effet de serre.

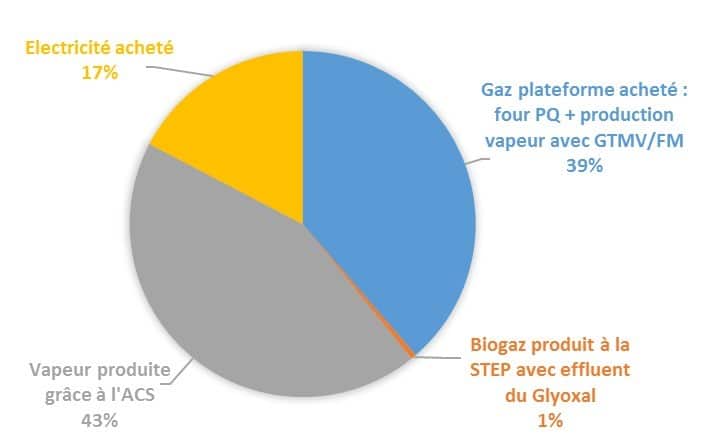

Quelles énergies consomme la plateforme :

Que représente notre consommation d’énergie? Consommation plateforme = 31 530 tep (Tonnes Equivalent Pétrole)

Cela correspond à 4 637 Américains ou 8 522 Français

Une énergie décarbonée à 60 % !

La vapeur produite grâce à la fabrication de l’Acide Sulfurique et le biogaz produit à la STEP sont neutres d’un point de vue environnemental car issus d’énergies fatales. L’électricité achetée est une électricité décarbonée à près de 93 %.

Transport des matières

Le rythme de la production sur le site de Weylchem Lamotte conditionne les flux de marchandises qui entrent et sortent du site. Afin de limiter les risques industriels, le stockage de matières est optimisé au maximum.

Le site dispose d’un embranchement ferroviaire privé et de plusieurs dessertes ferroviaires chaque semaine.

Des matières transitent quotidiennement par camions.

L’un des objectifs du développement durable est de réduire le trafic de certains produits en gagnant toujours plus d’autonomie dans les cycles de production.

80 camions par jour

(Jusqu’à 2 000 tonnes)

1 train par jour

(Jusqu’à 960 tonnes)

Les déchets

Tout d’abord, notre démarche d’amélioration continue porte sur la non-production à la source des déchets. Ensuite, les déchets générés par l’activité de la plateforme sont triés et éliminés par catégorie.

Les différents déchets :

- Déchets banals : 120 tonnes

- Déchets triés (métaux bois, plastiques, verre, carton) : 400 tonnes

- Déchets industriels dangereux : 3000 tonnes

- Boues de la Station d’Epuration : 19000 tonnes par an

Les déchets Banals non valorisables

Ce sont les déchets qui ne sont pas dangereux et qui ne sont pas valorisables (poubelles de bureaux, déchets « ménagers » etc …).

Ils sont collectés en bennes et éliminés, comme les ordures ménagères car ils sont de même nature et représentent moins de 200 t/an (c’est-à-dire moins qu’un village de 1 000 habitants).

Les déchets triés et valorisés :

Ce sont tous les déchets qui sont triés pour être valorisés :

- Ferrailles, cuivre, inox, câbles,

- Carton, plastiques non souillés,

- Le verre,

- Les cartouches d’imprimante

- Le bois.

- Les déchets électriques et électroniques

Ils représentent aujourd’hui près de 400 tonnes par an.

Les boues

Depuis 2019, 100 % des boues de la station d’épuration sont valorisées dans le milieu agricole. L’impact sur l’agriculture est bénéfique puisque l’objet de cette filière vise à satisfaire une partie des besoins des plantes et des sols.

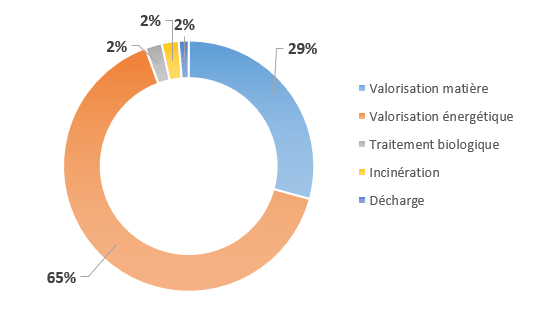

Au total sur l’ensemble des catégories de déchets, plus de 98% sont valorisés soit pour la matière soit pour l’énergie.

Les déchets Banals non valorisables

Ce sont les déchets qui ne sont pas dangereux et qui ne sont pas valorisables (poubelles de bureaux, déchets « ménagers » etc …).

Ils sont collectés en bennes et éliminés, comme les ordures ménagères car ils sont de même nature et représentent moins de 200 t/an (c’est-à-dire moins qu’un village de 1 000 habitants).

Les déchets triés et valorisés :

Ce sont tous les déchets qui sont triés pour être valorisés :

- • Ferrailles, cuivre, inox, câbles,

- • Carton, plastiques non souillés,

- • Le verre,

- • Les cartouches d’imprimante

- • Le bois.

- • Les déchets électriques et électroniques

Ils représentent aujourd’hui près de 400 tonnes par an.

Chiffres :

- Déchets banals : 160 tonnes par an

- Déchets triés (métaux bois, plastiques, verre, carton) : 300 tonnes par an

- Déchets industriels dangereux : 3000 tonnes par an

Pourcentage par type traitement