For 125 years, the different owners of the platform have always preserved the quality of life of employees, residents and the surrounding nature. Today, our approach to continuous improvement takes the environment into account from the design of a product, a process, throughout its life to its disposal.

.

WeylChem Lamotte is a signatory to the Responsible Care which ensures the global commitment of the chemical industry to the safe management of chemicals throughout their lifecycle and to the promotion of their role in improving the quality of life and their contribution to sustainable development.

WeylChem Lamotte is an establishment subject to the legislation of Classified Facilities for Environmental Protection (ICPE) and is classified as SEVESO High Threshold which implies enhanced monitoring and the impact of the platform activity is controlled by internal and external laboratories at the request of the administration which verifies the results and carries out unannounced controls.

These management systems are certified: ISO 14001 Environment ISO 50001 Energy

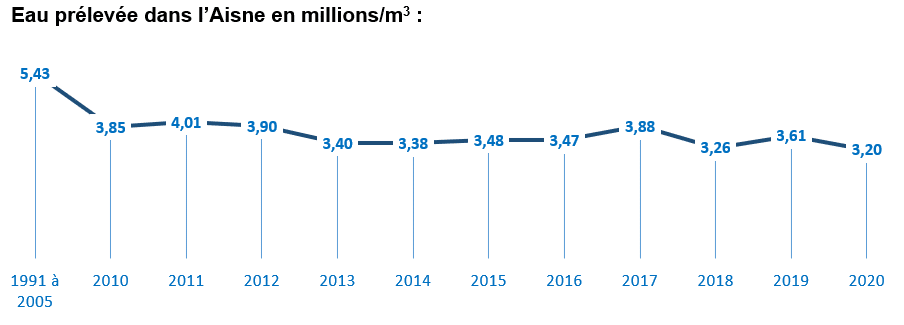

Reduction of water consumption

For many years, the platform has been committed to a policy of reducing its water consumption and preserving the water quality of the Aisne.

These actions have reduced the amount taken from the river by approximately 2 million m3/year, or about 37.5% since 2005.

Purification Station

Processing capacity equivalent to a city of 300,000

The continuous improvement of the water treatment plant’s performance is an ongoing objective that reduces the impact on the quality of the natural environment. Over the past 3 years, €1 million has been invested in the automation and monitoring of the station as well as in the separation of incoming flows.

Methanizer

A methanizer processes a specific effluent whose biogas produced is valued in the main boiler of the platform.

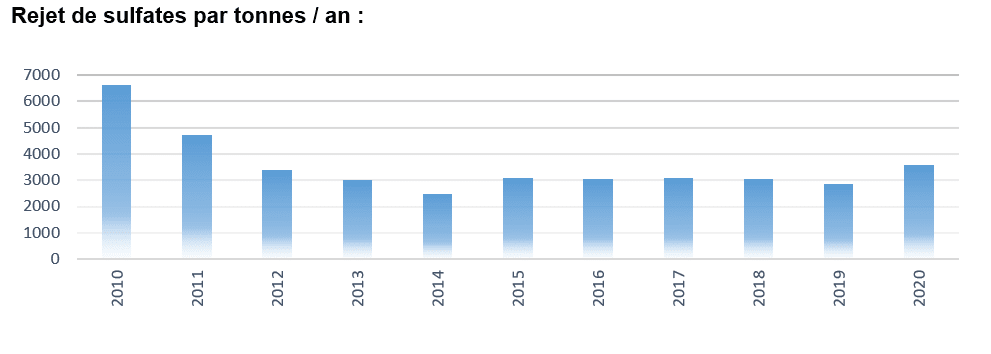

Recovery of sulphates

A pre-treatment unit recovers and recovers the sulphates contained in the effluent from a production workshop on the detergence market.

Pretreatment of nickel

Commissioning of a pre-treatment of nickel contained in the effluent of an agro-chemical production unit in 2015.

As part of the national research program for hazardous substances in water, pretreatment of a production effluent resulted in a 70% reduction in the release of nickel into the Aisne

Sludge

Since 2019, 40% of the sludge from the wastewater treatment plant has been upgraded in the agricultural sector. The impact on agriculture is beneficial since the aim of this sector is to satisfy part of the needs of plants and soils.

Daily self-monitoring makes it possible to check the quality of the water discharged after treatment in the natural environment.

For more than ten years, an annual hydrobiological assessment carried out during low-grade periods has confirmed the low impact of the platform’s activity on the quality of the Aisne.

Air

Reduction of greenhouse gases

The production of the Glyoxal and Glyoxylic Acid units leads to a significant emission of a greenhouse gas; nitrous oxide (N2O) whose warming power is 298 times higher than carbon dioxide.

As early as 1993, tests were launched to test different N2O destruction processes. These tests led in 1997 to the development of a patented catalytic destruction process and the construction of an industrial N2O emission treatment unit.

The performance and capacity of this unit has been improved to achieve a yield greater than 90%.

Reduction of Nox emissions

Since 2005

Reduction of acidifying gases

Building on the experience gained in catalytic treatment of nitrous oxide, the platform invested in catalytic treatment of nitrogen oxides.

NOx emissions

Since 2005

Environment and transport

Energy production and consumption

WeylChem Lamotte is ISO 50001 certified. This international standard aims to improve energy performance. It aims to address the scarcity of energy and its sustainable price increase, while contributing to the reduction of greenhouse gas emissions.

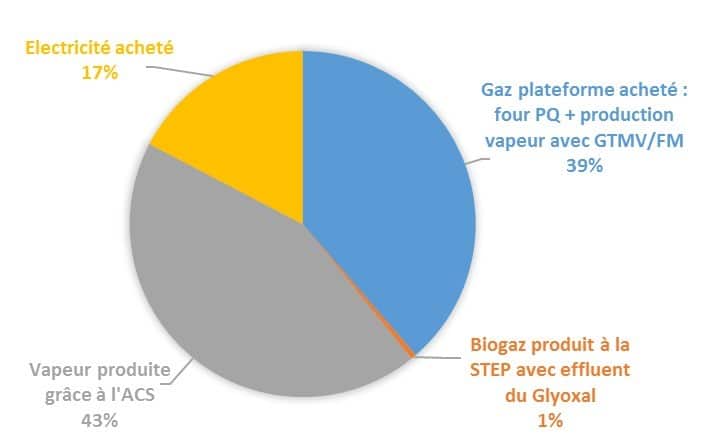

Which energies consume the platform:

What does our energy consumption represent? Platform consumption = 31,530 toe (Tonnes Oil equivalent)

This corresponds to 4,637 Americans or 8,522 French

A 60% decarbonized energy!

The steam produced by the manufacture of Sulphuric Acid and the biogas produced at the WWTP are neutral from an environmental point of view because they come from lethal energies. The electricity purchased is nearly 93% carbon-free.

Material transport

The pace of production at the Weylchem Lamotte site determines the flow of goods into and out of the site. In order to limit industrial risks, the storage of materials is optimized to the maximum.

The site has a private railway branch line and several rail services every week.

Materials are transported daily by trucks.

One of the objectives of sustainable development is to reduce the traffic of certain products by gaining ever more autonomy in the production cycles.

80 trucks per day

(Up to 2000 tonnes)

1 train per day

(Up to 960 tonnes)

Waste

Our continuous improvement approach focuses on non-production at the source of the waste. The waste generated by the platform activity is sorted and disposed of by category.

Non-recoverable Ordinary waste

This is waste that is not hazardous and is not recoverable (office waste bins, household waste, etc.).

They are collected in dumpsters and disposed of, like household waste because they are of the same nature and represent less than 200 t/year (that is to say less than a village of 1,000 inhabitants).

Sorted and recovered waste:

All waste is sorted for recovery:

- • Scrap, copper, stainless steel, cables,• Cardboard, clean plastics,• Glass,• Printer cartridges• Wood. • Electrical and electronic waste

Today they represent nearly 400 tonnes per year.

Numbers:

Ordinary waste: 160 tonnes per year

Sorted waste (wood, plastic, glass, cardboard): 300 tons per year

Hazardous industrial waste: 3000 tonnes per year

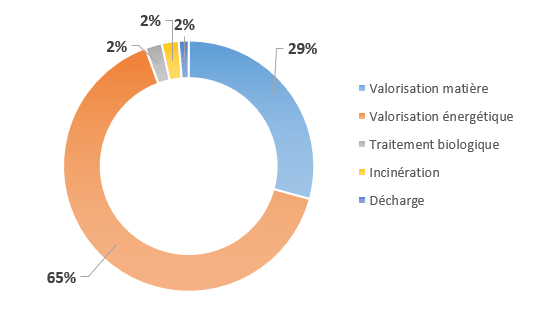

Percentage by type of treatment